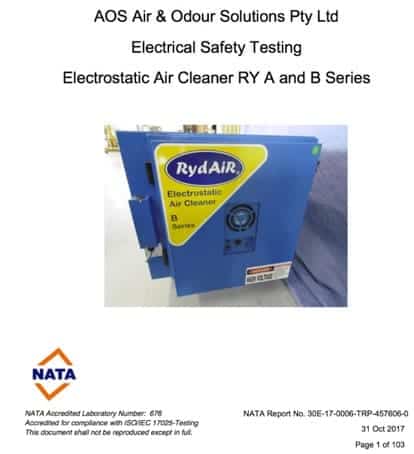

The electrostatic filtration model RY – A & B series all comply and certified with requirements of standard with (AS/ NZS60335.1 2011 + A1, A2, A3).

The electrostatic filtration model RY – A & B series all comply and certified with requirements of standard with (AS/ NZS60335.1 2011 + A1, A2, A3).

It’s an offense to supply or offer prescribed electrical equipment unless it’s approved or certified. Electrical safety of the RY series electrostatic filtration units are important for manufacturers, consumers and authorities. The electrostatic electrical safety testing helps ensure public safety as only electrostatic filtration products are conforming to the relevant standards are permitted to be offered for sale.

The electrical testing on the electrostatic filtration unit of the RY series A & B included procedures below:

GLOW WIRE TESTING

Glow wire testing is an electrical safety test designed to evaluate the flame resistant properties of plastic materials used in electrostatic air cleaner devices. Its purpose of this test is to protect itself against overheating or electrically energized parts which may cause the plastic material to ignite. This may occur in normal use, under reasonable abnormal use, malfunction or failure of the electrostatic air cleaner product. The glow wire simulates an overheated part which comes then comes into contact with plastic materials in the manufacturing of the electrostatic air cleaner.

BALL PRESSURE TESTS

Ball pressure test is carried out to check the resistance to heat of nonmetallic parts at elevated temperatures in the electrostatic air cleaner. The ball pressure apparatus is placed under test, inside the oven and the temperature is 75 degrees Celsius for external parts and 125 degrees Celsius for parts holding current carrying connections and the duration of testing will last 60 minutes.

NEEDLE-FLAME TEST

This method is used to test and assess the fire hazard of the electrostatic filtration unit presented by plastic material using a material flame. This test on the electrostatic air cleaner determines the impact of the small flame on the test specimen, in particular it calculates the severity of the exposure time to the flame after which the material will just meet the specified requirements. The test specimen is arranged in a vertical position over tissue paper and a propane gas flame is applied to the edge as well to the flat surface. The burning time, flammability and severity, exposure time are determined for this flame application. The testing of the electrostatic filtration unit is performed on selected areas of these parts.

COMPARATIVE TRACKING INDEX (CTI)

The comparative tracking index (CTI) is the maximum voltage measured in volts at which the air filtration system material withstands 50 drops of contaminated water without tracking. Tracking is defined as the formation of conductive paths due to electrical stress, humidity, contamination. The CTI test of electrostatic equipment provides an accelerated simulation of conditions of surface discharges and possible resulting tracking and failure of equipment using insulating materials. The testing of the electrostatic precipitator comparing insulated materials under wet materials and contamination.