The new ASHRAE standard test 52.2 2102 provides the first industry accepted procedure for measuring electrostatic filters see below. The AOS electrostatic precipitators have been tested to ASHRAE 52.2 2012 and EN 7709 DOP TEST and extracts are reproduced for reference.

PARTICLE SIZE RANGES

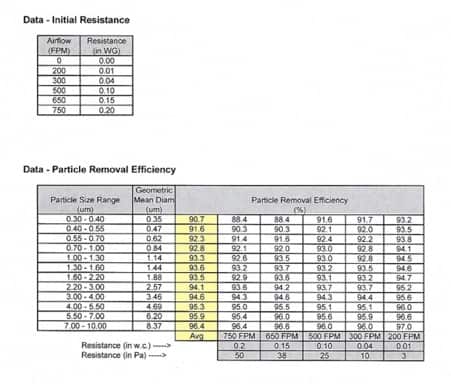

The ASHRAE 52.2 test and certification procedure calls for electrostatic filter efficiency measurement to be taken on twelve (12) particle ranges.

For reporting and rating purposes these (12) ranges are grouped into (3x) wider ranges

E1 – 0.3 microns

E2 – 1.0 microns

E3 – 3.0 – 10 microns

Efficiency measurements are taken on each of the twelve (12) particle size range at (6) different points during the test.

– Clean (after) 4 increments of dust loading.

– After the final resistance has been recorded.

E3 – 3.0 – 10 microns

Efficiency measurements are taken on each of the twelve (12) particle size range at (6) different points during the test.

– Clean (after) 4 increments of dust loading.

– After the final resistance has been recorded.

The six (6) efficiency measurements for each twelve (12) particle size range and 72 total efficiency measurements are taken by challenging the filter with potassium chloride (KCI) particles over the entire range of 0.3 to 10.0 microns require the test procedure.

The lowest efficiency value (of the six) measurements were taken throughout the electrostatic filter test for each of twelve (12) particles sizes range aren’t averaged and the lowest efficiency.

These values are the averaged particle sizes efficiency (PSE) for each range. The PSE values are used to classify the filter into one of the sixteen (16) minimum efficiency reporting values (MERV) ratings.

AOS electrostatic precipitator has been independently tested by Blue Haven technologies KY, USA. They have been certified and tested to ASHRAE 52.2 2012 and test reports (extracts are reproduced for reference).

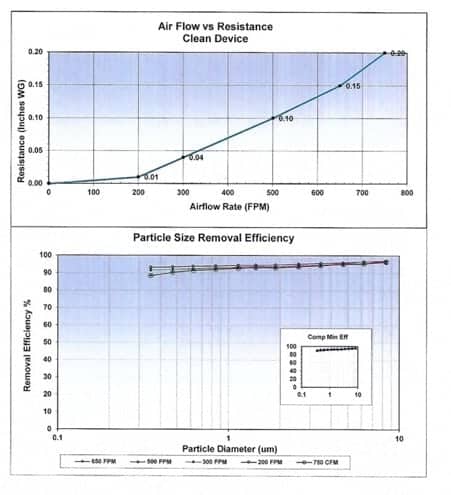

The independent ASHRAE 52.2 2012 testing included airflow vs resistance and particle size removal efficiency, data initial resistance, data – particle removal efficiency and certified and tested to Australian standard 1668 parts 1 & 2 and BCA performance requirements FP4.3, FP4.4, FP4.5, F4.0, FP4.12.

Air quality assessment was undertaken by KMH environmental and a heritage building which was located @ City Recital Hall – 1 Angel Place Sydney as per requirement by City of Sydney as per requirement for smoke and odour sampling was required from a previous AOS electrostatic precipitator system project. Experience has shown that the AOS electrostatic filtration method provides adequate dispersion of exhaust gases and smoke to minimise impacts on adjacent properties especially smoke and odour (Extracts can be reproduced for reference).

The smoke and odour sampling @ City Recital Hall (1 Angel Place, Sydney NSW 2000) concluded that the AOS electrostatic air cleaning system should not present a problem air quality issues including smoke and odour nuisance for nearby restaurants, commercial and retail properties hospitals and pedestrians.

AOS (B-Model) electrostatic filter units have been independently CE certified to the following directives below:

(2006/95/EC Low Voltage, 2004/108/EC Electromagnetic compatibility) (Certificate available for requests).